When it comes to finding the perfect material for your creative project, the vibrant world of acrylic sheets offers a pallet of options. Whether you’re an artist crafting a masterpiece, a fabricator engineering a prototype, a sign maker advertising to the masses, or a retailer displaying goods, the choice of color and opacity in your acrylic can dramatically affect the final outcome.

In this guide, we'll provide insights into selecting the right acrylic sheet based on color and opacity, touching on clear, translucent, opaque, UV-blocking, mirror, matte, and anti-glare options.

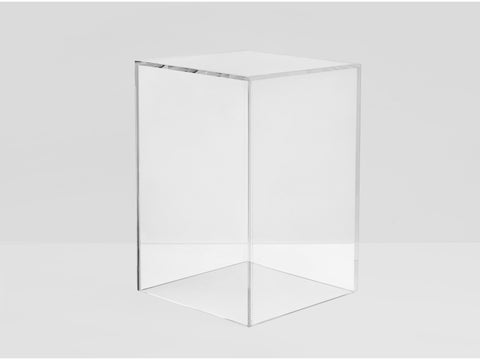

Clear Acrylic

Clear acrylic is prized for its clarity and transparency. Resembling glass in appearance but lighter in weight and more resistant to impact, clear acrylic is widely utilized across numerous industries and applications. Available in sheets or blocks, it can be easily machined, thermoformed, or molded into various shapes and sizes, making it adaptable to diverse manufacturing processes.

Commonly employed as a lightweight and durable alternative to glass, transparent acrylic finds its way into architectural glazing for windows and skylights, as well as in display cases, shelving and stands for retail environments, museums, and exhibitions. Its optical properties also make it suitable for signage and advertising displays, allowing for the clear display of graphics and messages.

Additionally, clear acrylic serves in lighting fixtures, medical devices, and even aquariums and fish tanks, where its clarity, biocompatibility, and ability to be formed into complex shapes are highly advantageous. Overall, clear acrylic combines optical clarity, durability, and versatility, making it a favored material for a wide array of applications across various industries.

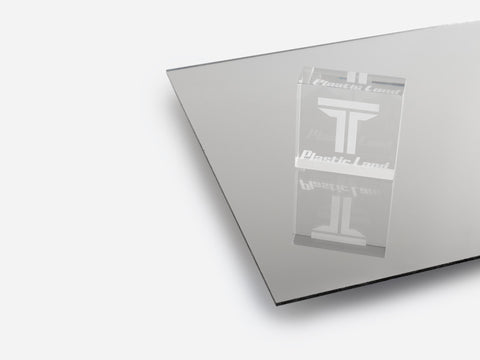

Mirror Acrylic

Mirror acrylic, also known as mirrored acrylic or acrylic mirror, is a type of acrylic material that has a reflective surface resembling that of a traditional glass mirror. It is created by applying a thin layer of reflective material, such as aluminum or silver, onto one side of a clear acrylic sheet. This reflective coating provides a mirror-like finish while retaining the lightweight and shatter-resistant properties of acrylic.

Mirror acrylic is commonly used in applications where a lightweight and shatter-resistant alternative to glass mirrors is desired. It is often utilized in interior decoration, retail displays, signage, theatrical props, and cosmetic mirrors. Mirror acrylic is available in various colors and finishes, including standard silver, gold, bronze, and even tinted options, offering flexibility in design and aesthetic choices.

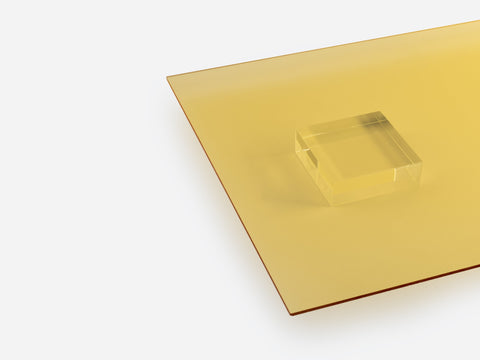

Colored Transparent Acrylic

Colored transparent acrylic, also known as transparent acrylic, is a variant of acrylic material that retains the inherent transparency of traditional clear acrylic but is infused with pigments or dyes to impart a specific color. This type of acrylic maintains the clarity and translucency characteristic of acrylic while offering a range of vibrant colors and hues.

Manufactured in sheets or blocks, colored transparent acrylic finds widespread use in various applications where both color and transparency are desired. It is commonly employed in signage, displays, architectural elements, artistic installations, and decorative accents. Additionally, colored transparent acrylic can be machined, thermoformed, or molded into different shapes and sizes, providing flexibility in design and creative possibilities.

Translucent Acrylic

Translucent acrylic is a type of acrylic material that allows light to pass through but diffuses it in such a way that objects or images behind it are not clearly visible. Unlike transparent acrylic, which offers a clear view through the material, translucent acrylic softens and disperses light, creating a semi-opaque appearance.

Manufactured in sheets or blocks, translucent acrylic is commonly used in applications where diffused lighting or privacy is desired while still allowing some level of light transmission. It is available in various colors and opacities, with some variants allowing more light to pass through than others.

Translucent acrylic finds applications in architectural elements, decorative lighting fixtures, privacy screens, signage, and artistic installations. Its ability to diffuse light evenly makes it suitable for creating a soft, ambient glow in interior spaces or for concealing objects or structures while still allowing some illumination to pass through. Additionally, translucent acrylic shares many of the properties of standard acrylic, such as durability, weather resistance, and ease of fabrication.

Opaque Acrylic

Opaque acrylic is a type of acrylic material that lacks transparency, meaning it does not allow light to pass through and cannot be seen through. Unlike transparent or translucent acrylic, which allows for the transmission of light, opaque acrylic blocks or reflects light, obscuring any objects or images behind it.

Manufactured in sheets or blocks, opaque acrylic is available in a variety of colors and finishes, including solid colors and textured surfaces. This material is commonly used in applications where privacy, light blocking, or specific color requirements are necessary.

Examples of applications for opaque acrylic include signage, privacy screens, architectural elements, automotive components, and decorative panels. Opaque acrylic shares many of the properties of transparent acrylic, such as durability, weather resistance, and ease of fabrication. However, its lack of transparency makes it suitable for different types of applications where visibility is not desired.

Fluorescent Acrylic

Fluorescent acrylic sheets are a specialized type of acrylic material that contains fluorescent additives or pigments, which absorb ultraviolet (UV) light and emit visible light at a different wavelength. This property causes the acrylic sheet to glow brightly when exposed to UV light sources such as blacklights.

Manufactured in sheets or blocks, fluorescent acrylic sheets are available in a variety of vibrant colors that emit intense, glowing hues when illuminated with UV light. These sheets are commonly used in applications where a bright, eye-catching display or signage is desired, such as in nightclubs, bars, theaters, amusement parks, and themed events.

Fluorescent acrylic sheets are also utilized in artistic installations, architectural accents, and decorative lighting fixtures to add dynamic visual effects. Additionally, they can be machined, cut, and shaped into various forms, offering flexibility in design and creative possibilities.

It's important to note that while fluorescent acrylic sheets emit vibrant colors under UV light, they may appear dull or muted under normal lighting conditions. Therefore, their visual impact is best achieved in environments where UV light sources are present.

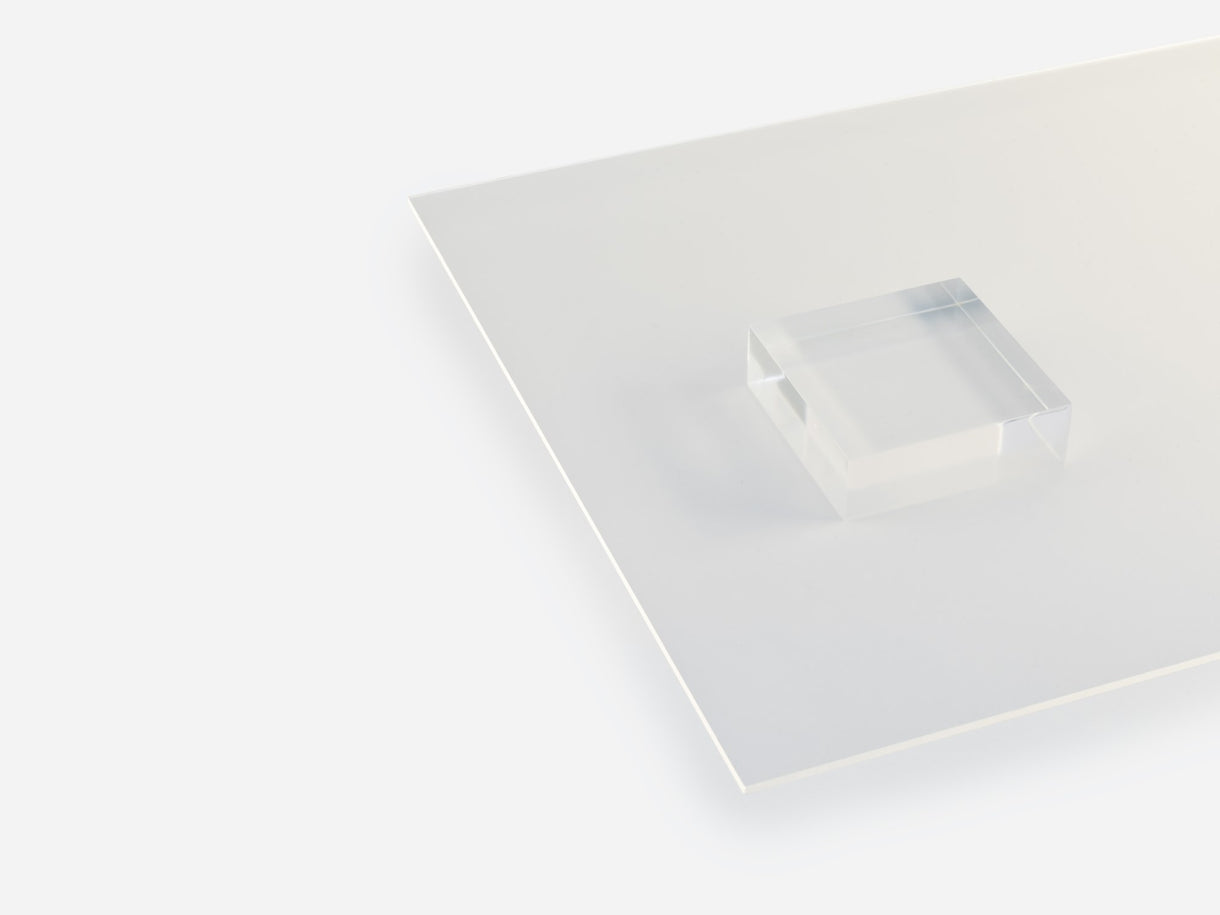

Matte Acrylic or Frosted Acrylic

Matte acrylic and frosted acrylic sheets are specialized types of acrylic material that have been treated or processed to produce a non-reflective, diffused surface finish. This finish gives the acrylic a soft, satin-like appearance and texture, rather than the glossy finish typically associated with standard acrylic.

Manufactured in sheets or blocks, matte acrylic sheets are often used in applications where a more subtle or muted aesthetic is desired. The frosted surface diffuses light, reducing glare and reflection, making it ideal for applications such as privacy screens, partitions, decorative panels, and lighting fixtures.

These acrylic sheets can be found in various thicknesses, colors, and opacities to suit different design requirements. They can also be easily cut, shaped, and fabricated using common tools and techniques, allowing for flexibility in design and customization.

Frosted acrylic sheets offer the same durability, weather resistance, and ease of fabrication as standard acrylic, making them suitable for both indoor and outdoor applications. Their soft, diffuse appearance adds a touch of elegance and sophistication to any project.

Non-Glare Acrylic

Non-glare acrylic sheets, also known as anti-glare acrylic, are specialized types of acrylic material designed to reduce glare and reflections on their surface. This is achieved through a treatment or process that creates a matte finish, diffusing light and minimizing reflections.

Manufactured in sheets or blocks, non-glare acrylic sheets are commonly used in applications where glare reduction is essential for optimal visibility. They are often employed in picture frames, display cases, signage, and protective covers for electronic displays such as monitors and tablets. By reducing glare, these acrylic sheets enhance readability and viewing comfort, especially in environments with bright or harsh lighting conditions.

Non-glare acrylic sheets are available in various thicknesses, sizes, and finishes to suit different needs and preferences. They offer the same durability, weather resistance, and ease of fabrication as standard acrylic, making them suitable for both indoor and outdoor use. Additionally, they can be easily cut, shaped, and fabricated using common tools and techniques, providing flexibility in design and customization.

Overall, non-glare acrylic sheets provide an effective solution for minimizing reflections and improving visibility in a wide range of applications, enhancing the overall viewing experience.

UV Acrylic

UV acrylic, also known as ultraviolet (UV) transmitting acrylic or UV-transparent acrylic, is a specialized type of acrylic material designed to allow ultraviolet light to pass through while blocking or minimizing the transmission of visible light. This unique property makes UV acrylic ideal for applications where ultraviolet light needs to be transmitted while simultaneously blocking visible light.

Manufactured in sheets or blocks, UV acrylic is commonly used in industries such as aerospace, automotive, medical, and scientific research. Some common applications include ultraviolet (UV) lighting systems, UV sterilization equipment, phototherapy devices, UV curing systems, and optical instruments. UV acrylic offers several advantages, including high optical clarity, excellent UV transmission properties, and durability. It is also resistant to yellowing and degradation caused by prolonged exposure to ultraviolet light.

Additionally, UV acrylic can be easily machined, cut, and fabricated using common tools and techniques, allowing for flexibility in design and customization. Overall, UV acrylic provides a reliable and efficient solution for applications requiring the transmission of ultraviolet light while offering durability and optical clarity. Its unique properties make it an essential material in various industries where precise control of ultraviolet light is critical.

Two-Way Mirror

A two-way acrylic mirror, also known as a one-way acrylic mirror or semi-transparent acrylic mirror, is a specialized type of mirror made from acrylic material. It possesses the unique property of being partially reflective and partially transparent, depending on the lighting conditions on each side of the mirror. In practical terms, when one side of the two-way acrylic mirror is brightly lit and the other side is dimly lit, the brightly lit side functions as a mirror, reflecting the image of objects or people in front of it.

Meanwhile, the dimly lit side appears transparent, allowing observers on that side to see through the mirror and observe the area beyond it. Two-way acrylic mirrors are commonly used in applications where one-way visibility is desired for privacy or security purposes.

Two-way Mirror Acrylics find use in settings such as surveillance rooms, interrogation rooms, observation decks, and theatrical productions. These mirrors are manufactured by applying a thin, partially reflective coating onto one side of an acrylic sheet, allowing for the selective reflection of light while permitting some light transmission, thereby creating the distinct two-way effect.

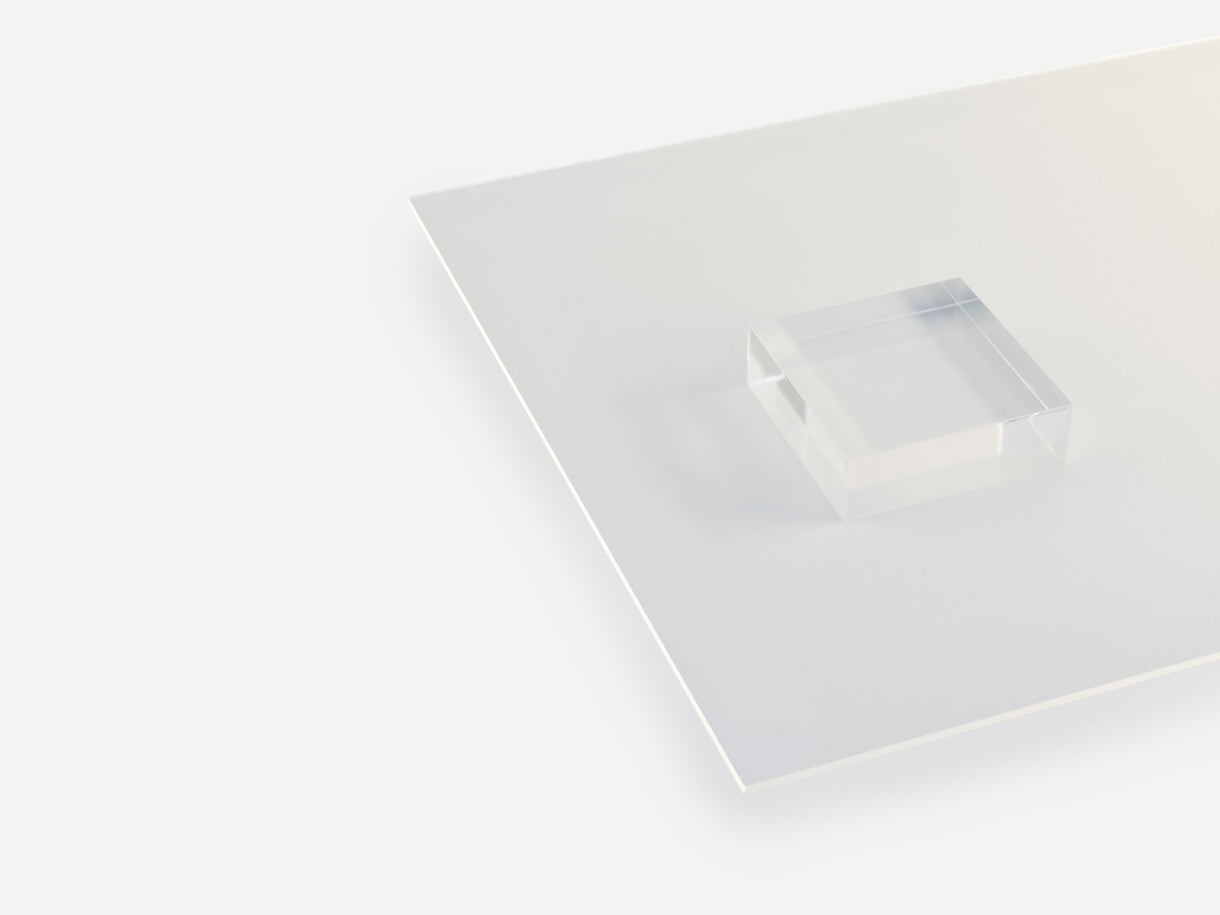

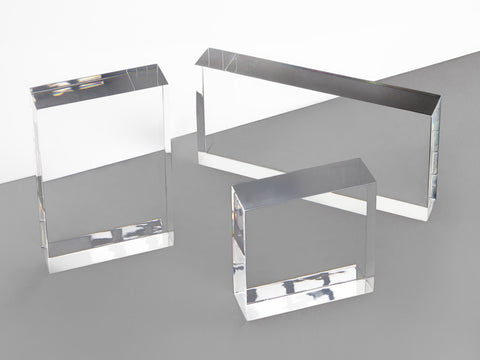

Acrylic Blocks

Acrylic blocks, also referred to as acrylic slabs, solid acrylic panels, photo blocks or acrylic monoliths, are substantial pieces of acrylic material known for their robustness and optical clarity. These blocks, which can range from several inches to several feet in thickness, are typically crafted through processes like casting or machining acrylic resin into solid forms of desired dimensions.

Widely utilized across industrial, commercial, and artistic sectors, acrylic blocks find applications in architectural elements, signage, displays, art and sculpture, jewelry displays, medical and laboratory equipment, and optical components. Often valued for their durability, resistance to weather and chemicals, and ease of fabrication, thick acrylic blocks offer versatility in design and can be customized with various finishes, colors, and textures to suit specific project requirements.

Acrylic blocks serve as sturdy bases for signage and displays in retail environments, provide structural support in architectural designs, and enable the creation of intricate artworks and optical instruments.

Acrylic Rods and Tubes

Acrylic rods and tubes are versatile materials that can be used for a wide range of applications. They are commonly used in lighting fixtures, displays, and architectural designs due to their ability to transmit light effectively. T&T Plastic Land offers acrylic rods and acrylic tubes in various sizes and shapes to suit different needs. The difference between rods and tubes is simple: acrylic rods are solid throughout, while acrylic tubes are hollow in the center.

Still not sure? Ask the pros at T&T Plastic Land

Your project's success might hinge on the right choice of acrylic, and each type offers a unique set of features and benefits that can elevate your work. Always consider the ambient conditions, the desired aesthetic, durability requirements, and the message you wish to convey when choosing your acrylic.

We hope this guide provides a clearer vision of how to bring your ideas to life with acrylic sheets. Remember, the right color and opacity not only reflect your vision but can also influence the reaction it inspires.

Your #1 source for acrylic sheets and more

Explore the extensive acrylic selection at T&T Plastic Land to discover the ideal match for your upcoming project. Please contact us if you require guidance in selecting the appropriate acrylic or if you are unable to locate your desired option. We have a huge array of custom options available, and our expert staff is standing by to help you find what you're looking for.